How to cover the floor in the garage: 10 best materials

For most car owners, a garage is a special place where you can not only leave the car at night, but also spend hours on end, performing minor car repairs. Many even turn the garage into a workshop and even a place to meet friends. Such multitasking puts forward special requirements for the decoration of the garage - everything must be done in it so that the car and its owner are completely safe and comfortable. The floor takes the biggest hit, because it is precisely on it that the car will constantly drive, fuels and lubricants can spill onto it and heavy tools can fall on it. The flooring must endure all these influences, so sooner or later every car owner asks what to cover the floor in the garage. We hasten to offer you some of the best options.

What should be the floor in the garage?

Not every flooring material can be used in a garage. The coating must meet the following requirements:

- withstand regular loads from the mass of the car. In addition, garages often store heavy tools that also exert pressure on the floor;

- strength. On the floor will fall not only the load from the car, but also from the fall of a heavy tool;

- moisture resistance. When it is raining or snowing outside (and in some regions it has been snowing for more than six months), the vehicle will bring moisture to the garage on wheels and on the body, so the floor should not be rotted or formed mold;

- resistance to aggressive substances. Car maintenance involves the use of gasoline, a cleaner, antifreeze, oil, and other substances that, if caught on some materials, can damage them. For the garage, you should choose a coating that is not afraid of such an impact and can be easily cleaned from stains;

- fire resistance, since there will always be flammable liquids in the garage;

- resistance to temperature extremes. Most garages do not heating, and the air warms up there only when the car owner decided to tinker with the car. This means that the flooring will regularly suffer from temperature changes, and it is important that it does not become cracked or deformed.

You can also add to the list of requirements. profitability, because, what to dissemble, everyone wants to get the maximum by spending a minimum.

The requirements are strict, but car owners have a choice of suitable materials. Let's try to figure out which floor for the garage is better, and what are the main pros and cons of popular materials.

Option number 1. Earthen floor

This floor arrangement option can be described as “Cheap and cheerful.” It is unlikely that it will suit those who intend to build a major garage, providing complete safety for the car and comfort for its owner. This decision is in case of an extremely limited budget.

Advantages earthen floor in the garage:

- the relative cheapness of the arrangement;

- minimum time costs;

- only minimal construction skills are needed.

Disadvantages much more:

- earthen floor is a source of dust and dirt, and all this will settle on the car and things that are stored in the garage.If the earth is dry, then dust will rise when the car moves and people move. If water gets into the garage (for example, when it rains outside), then there will be a lot of dirt in the garage immediately;

- in the winter it will be very cold in the garage;

- no opportunity to hold warming;

- constantly have to add soil and tamp it, as noticeable depressions will form along the path of the car.

Arrange an earthen floor in the garage simple enough. They start work when the walls have already been erected. First, a fertile soil layer is taken out, this is about 15-40 cm depending on the region, then the base is covered with a plastic film or geotextile - This is a protection against the germination of grass. Now it remains to fill the recess with soil. First, a layer of not more than 5 cm is poured, it must be carefully tamped, then soil is still poured, tamped again, and so on, until the required level is reached. Please note that it is necessary to make a slight bias towards the gate.

Option number 2. Concrete floor

The concrete floor in the garage is classic. Concrete may be the basis for further decoration, and may be used on its own. Most garage owners prefer the concrete floor, and for good reason.

Benefits:

- high strength and durability, the ability to withstand severe loads, however, the magnitude of these loads greatly depends on the brand of concrete;

- Smooth surface;

- resistance to moisture, fire, temperature extremes and most aggressive substances;

- absence of harmful fumes;

- low cost;

- an opportunity to carry out work independently.

A concrete floor is an almost perfect solution for arranging a floor in a garage, but this option has some limitations:

- the floor surface is very cold, because if you often spend a lot of time in it in the winter, you will have to think about a heating system;

- if concrete is not processed in any way, then it will eventually wear off and dust;

- the complexity of the organization of the concrete floor;

- to work faster, you will need a special technique.

The floor in the garage can be equipped using factory concrete blocks or by pouring concrete directly on the spot building. Application finished blocks will significantly speed up the process of organizing flooring, in addition, the characteristics of the factory units are stable and checked by the factory. On the other hand, for the transportation of heavy finished blocks, special equipment will be needed, and there will be seams between the individual plates, therefore the technology of casting a monolithic plate is usually used.

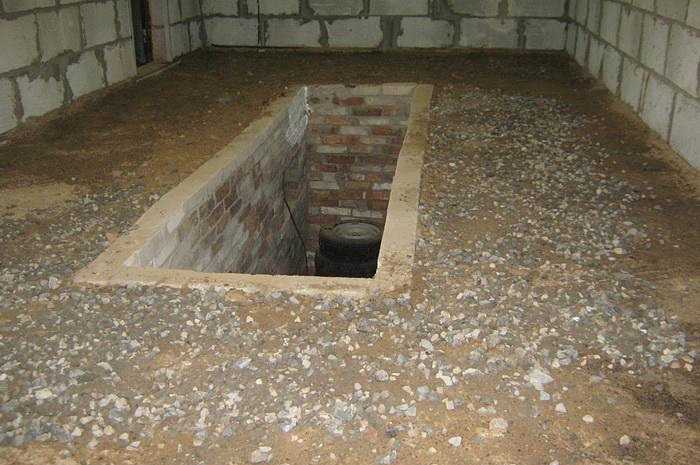

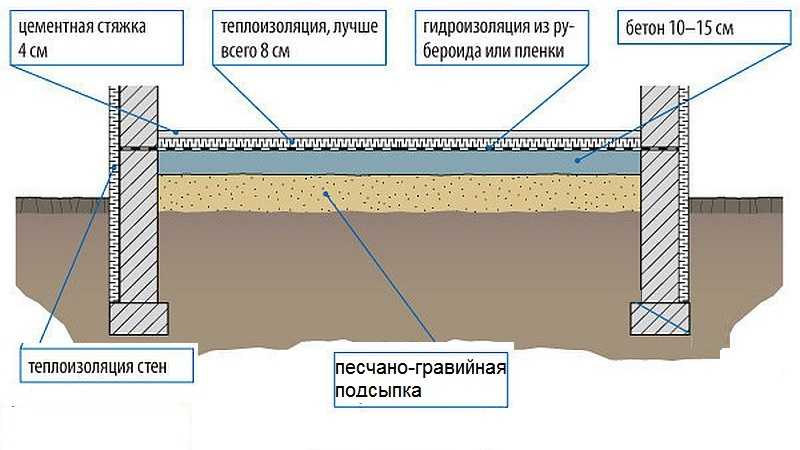

To equip concrete floor, first they take out the soil to a depth of 20-30 cm, fill up about 10 cm of rubble, tamp it, equip a sand cushion about 10 cm, it is also carefully tamped. On the the sand equip cement screed about 2 cm thick, then laid waterproofing material (for example, roofing material), and only after that it’s the turn to perform the main pouring of the concrete floor (thickness 5-7 cm), and it must be reinforced with steel fittings. As the concrete screed dries, it is periodically moistened with water. This will prevent the formation of cracks and provide proper strength to concrete. Naturally, the floor is made with a bias towards the gate.

When the concrete has gained strength, the garage can be safely operated, i.e. use screed as an independent floor covering. Some prefer not to dwell on this and use concrete only as a basis for further finishing the floor, for example, with porcelain stoneware, tiles or for pouring bulk floor.

The simplest option for finishing a concrete floor is coloring, and it becomes mandatory if, after drying, you rubbed the screed with the sole of the shoe and sand appeared. Such a floor will not last long, therefore it needs not so much decorative decoration as protection.

Option number 3.Self-leveling floors

Use of bulk floors allows you to quickly get a perfectly flat surface. Mixtures for bulk floors differ in composition and purpose. For example, cement and gypsum mixtures usually used for floor leveling. They do not allow you to create a decorative finish, but with their help you can very quickly and easily get rid of small bumps. Such compositions are inexpensive and quite easy to handle. To level the floor in the garage for finishing, it is better to use a cement poured floor, since gypsum is sensitive to high humidity.

Another thing - polymer bulk floorsthat are considered topcoat. The basis for them will be a concrete screed, on top of which a cement self-leveling floor can be used, since the base must be perfectly even.

TO advantages of polymer bulk floor The following qualities should be attributed:

- the durability of the coating, which is measured for decades;

- resistance to temperature changes and frosts, which is not uncommon in the garage;

- resistance to aggressive chemicals;

- resistance to fire;

- moisture resistance;

- hygiene and ease of cleaning.

Minuses:

- high cost of coverage;

- difficulties in the repair process. If any part of the coating is suddenly damaged, then it will be difficult to repair it due to difficulties with choosing the right shade.

The properties of the coating will depend on composition of the material used. Polymer bulk floors are:

- polyurethane floors the most expensive ones require very careful preparation of the base, but at the same time they are most resistant to shock loads and vibrations. The coating tolerates the effects of aggressive substances, moisture, and the fall of heavy objects is not scary for him. In addition, the coating is resistant to temperature extremes, it is easy to care for, and cracks and scratches are relatively easy to restore - even if you can damage the floor, the deformation should be sanded and varnished on top. It turns out the ideal version of the floor in the garage, and the distribution is constrained by the high price;

- methyl methacrylate floor Great for a garage. The coating is durable, wear-resistant, moisture-resistant, withstands the effects of chemically active substances. In addition, the floor freezes very quickly, and within a few hours after the installation is complete, you can walk and ride on it. The disadvantage is a pungent odor during drying, but with the organization of high-quality ventilation, it quickly disappears. During operation of the coating no extraneous odors will appear;

- epoxy floors also well tolerate abrasion, exposure to moisture, aggressive substances, temperature changes. The coating comes out solid and durable, but it has a significant minus - it is afraid of shock. Therefore, if you often make something in the garage and use a lot of heavy tools, it is better to look in the direction of other materials. If there are no particularly heavy objects that can fall in the garage, then an epoxy bulk floor is suitable for you;

- cement acrylic floor - This is the same cement bulk floor, but its characteristics are improved due to the presence of a polyacrylate copolymer. The coating is moisture resistant, resistant to aggressive substances, non-slip, perfectly withstands mechanical stress, but cracks can occur on the surface due to low elasticity.

The garage is not a place for intricate decor, but still some car owners will appreciate the opportunity to slightly transform the room, where enough time is spent. Polyurethane and epoxy bulk floors can be painted in any shade, and if desired, even add decorative chips (paint particles of different shapes and sizes) to simulate the surface of granite, marble, etc.You can, of course, apply a drawing, use a 3D image, and put coins, sand or other decorative elements under a layer of a transparent floor, but this is hardly appropriate in a garage.

Option number 4. Rubber floor

Another option that meets all the requirements for flooring in a garage is a rubber floor. The basis of the material is rubber crumb, which is mixed with adhesives, various modifiers and dyes. From this mixture rolls, tiles, rugs are made, liquid rubber is made.

Benefits:

- good resistance to shock loads, so that the fall of heavy objects to the material does not matter, and it can easily withstand the weight of the car;

- resistance to aggressive substances, moisture, temperature extremes;

- good indicators of heat and sound insulation;

- non-slip surface;

- high elasticity, therefore it is comfortable to walk on the rubber floor;

- durability;

- simplicity in leaving.

The material is not recommended for use near open sources of fire - this is the main limitation disadvantage coverings.

A rubber floor in the form of a garage is best suited for a garage. rolls. Thickness ranges from 2 to 12 mm, in the presence of cord reinforcement, giving the material additional strength. On sale you can find rolls of different colors, the coating is relatively easy to install, but over time it can peel off at the corners. Not bad also proved to be modular tilefrom which a pattern can be laid out on the floor. Installing such a coating is relatively simple, and in case of damage, individual tiles are easy to replace - you just need to take the material in advance with a margin. Another option is to equip a seamless coating by spraying liquid rubber. The main disadvantage of this option is the fear of shock loads.

Option number 5. Paving slabs

The original solution for arranging flooring in a garage is to use paving slabs. Not only will the garage have an aesthetic appearance, but also the material itself meets all the requirements for garage finishes.

Benefits:

- high strength - this floor can easily withstand regular loads from a moving car;

- moisture resistance;

- resistance to fire;

- excellent appearance, the ability to lay out a pattern;

- simplicity in leaving;

- relative simplicity in laying.

IN minuses often enter a price, but if you search, you can find more or less affordable options, but you should not go to extremes - too cheap tiles are unlikely to be of high quality. Often such products are made in small factories with poor equipment and without technology, therefore the quality will be appropriate. As for the installation, it is better to entrust it to professionals, but if you have some skills in the field of construction, then you can try to do it yourself.

Give preference to a tile with a rough surface - it will not slip. It is not worth taking too embossed tiles, since it will be more difficult to clean from dirt.

Styling process tiles in general terms are as follows. A soil layer of 20-30 cm thick is removed, a layer of gravel about 10 cm is poured, carefully rammed, a layer of sand about 5 cm thick is poured on top of it, it is also rammed. After this, a layer of sand is poured onto which the tile will be laid. Each element is carefully deepened into a sand cushion, the cracks are filled with sand or a mixture of sand and cement.

Option number 6. Porcelain Tiles

This option is not for those whose budget is limited. The material, although ideal for a garage, is expensive, because it is rarely used. Porcelain Tiles obtained by mixing clay, sand, feldspar, pegmatite and water. The mixture is subjected to high pressure and then high temperature. The result is a material that is not inferior in strength to natural stone.

Benefits:

- wear resistance and ability to withstand severe loads;

- resistance to moisture and fire;

- resistance to temperature extremes;

- durability up to 50 years;

- simplicity in leaving;

- great appearance.

IN minusesIn addition to the price, it is possible to attribute low heat-insulating qualities, as well as fragility, therefore, it is necessary to transport porcelain tiles with extreme caution. Lay the material on top of the concrete screed.

Option number 7. Acid resistant tile

This, of course, is not about tiledthat lies in the bathrooms and decorates the walls in the kitchen - such tiles will not withstand the loads characteristic of a garage. Will fit special acid resistant tile, which is usually used in the shops of industrial enterprises. The material is obtained on the basis of refractory clay, to which substances are added that provide resistance to negative environmental factors.

Pros:

- high strength and ability to withstand heavy loads. The material easily withstands the weight of heavy factory machines, so it will certainly bear the garage loads;

- moisture resistance;

- resistance to aggressive substances;

- resistance to temperature extremes and frosts;

- the tile does not absorb grease and dirt, therefore it is easy to clean;

- a non-slip surface will make moving around the garage safe in any weather.

Of cons it can be noted, perhaps, that there is a small assortment of shades of tiles, but when it comes to arranging a garage, not an apartment, this nuance is hardly worth referring to serious disadvantages.

Option number 8. Wooden floor

It is difficult to come up with more inappropriate material for the floor in the garage, but, nevertheless, many car owners still prefer this option. Why? Yes, because the tree has its own pros:

- low price;

- ease of installation. All work can be done independently;

- ease of repair. If any part of the floor is damaged, you can easily change several boards;

- good thermal insulation properties of wood make the stay in the garage more comfortable;

- environmental friendliness.

Cons quite a few:

- the tree is afraid of moisture, can rot, be affected by a fungus;

- wood is flammable;

- spilled fuel and lubricants are easily absorbed into the wood structure;

- the tree quickly abrades from constant contact with car tires.

To minimize the negative properties of the tree, it must be covered protective compounds, which will increase the resistance of the material to moisture and fire, protect it from attack by insects and mold. Additional protection will be paint. It is better to choose the most moisture-resistant rocks for the garage, for example, larch.

The wooden floor is lined with boards with a thickness of at least 40 mm, and it is better to take boards with a thickness of 50 mm or more. The wooden floor is laid on the logs, which are used as wooden blocks.

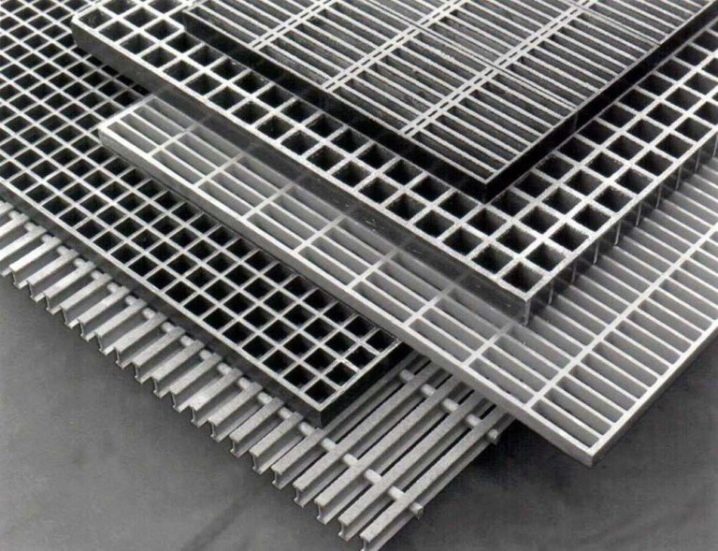

Option number 9. Steel floor

As a flooring for a garage, corrugated steel panels can be used. This option is not very common, but it has a lot the benefits:

- high strength and wear resistance, the ability to withstand decent loads;

- resistance to shock loads - the fall of even a heavy object will not leave cracks on the floor;

- non-slip surface;

- the material does not dust, therefore it is easy to clean;

- durability.

IN minuses it is worth attributing only the high price. Installation of steel plates is simple, but it is impossible to cut them yourself, so you need to make the right measurements and order products with the necessary parameters.

Option number 10. Asphalt

An interesting and not very common solution. If you have the opportunity to rent special equipment, then the option with an asphalt surface is worth considering. To his the benefits we attribute:

- resistance to temperature extremes;

- resistance to aggressive chemicals;

- good adhesion between asphalt and tires;

- seamless surface;

- high strength.

Although the cost of asphalt pavement is small, for its high-quality laying it is necessary to use the skating rink and invite specialists.Installation is carried out only in the warm season, otherwise the coating will not last long.

Before choosing a floor covering for a garage, carefully weigh its advantages and disadvantages, and also consider the features of installation, and, of course, take into account the cost of the material. Remember that the durability of the finish depends not only on the quality of the material itself, but also on the correctness of its installation.