6 innovations and modernizations of concrete

Concrete refers to specially created (artificial) stone building materials. It consists of water, an astringent (most often - cement) and fillers of different sizes. Concrete is one of the most widely used building materials in the world. This is the material of choice for most new large roads, buildings, bridges and many other structures because of its durability and relative ease of use. Technologies do not stand still, research teams conduct new research with the material presented, as a result of their work, new developments appear.

Concrete made of wood: reality or myth?

Previously, wood was one of the most common building materials, but today it was replaced by concrete mixes. Active development of technologies has allowed to combine 2 types of materials, creating a combined mixture of wood and concrete.

The Swiss National Resource Wood Program (NRP 66) focuses on creating a unique blend. Swiss researchers have managed to develop a radical approach to the combination of wood and concrete: they make resistant concrete, 50 percent of which is made of wood. The high content of wood in the concrete mixture contributed to a good thermal insulation of the material without compromising fire resistance.

The main difference between the described mixture and classical concrete is the replacement of gravel and sand fine-grained wood.

Making floating concrete

“They weigh no more than half what ordinary concrete weighs - the lightest of them even float!” Says the research organizer. In addition, after dismantling, the materials can be reused as fuel for heat and electricity. Despite compliance with fire safety requirements building material can be burned in conjunction with other waste.

The results of stress tests confirmed that the new wood concrete is suitable for the manufacture of slabs and wall panels and can become a material for load-bearing structures in construction. In the course of the upcoming studies, it is required to find out in which areas it is better to apply a certain type of wood-concrete composite and effective methods of its production. According to Daya Zwiki (organizer), the level of knowledge required for widespread use is still too limited.

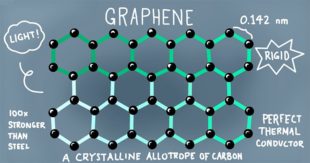

Revolutionary graphene concrete

Graphene is a carbon modification that has been gaining popularity recently. Experts from the University of Exeter have developed an innovative technique using nano-engineering to introduce graphene into the classical production of concrete mixtures. A unique technology has created durable, environmentally friendly, and durable concrete. In addition, the water resistance has increased significantly. Testing of the material produced has proved full compliance with British and European building standards.

Graphene is a carbon modification that has been gaining popularity recently. Experts from the University of Exeter have developed an innovative technique using nano-engineering to introduce graphene into the classical production of concrete mixtures. A unique technology has created durable, environmentally friendly, and durable concrete. In addition, the water resistance has increased significantly. Testing of the material produced has proved full compliance with British and European building standards.

It is important to note that the new graphene-reinforced concentrate significantly reduced the carbon footprint of traditional concrete production methods, making it more sustainable and environmentally friendly. At the same time, carbon emissions were significantly reduced (by 446 kg / t), and the amount of materials needed to create concrete was reduced by 50 percent.Most scientists are confident that the new technique will allow the introduction of new nano-materials into concrete, thus modernizing the global construction industry.

The search for green building methods is a step towards reducing carbon emissions worldwide and a way to protect the environment. This is an important investment in creating a progressive construction industry for the future.

Coal ash in concrete

It is difficult to obtain the exact moisture content inside the concrete, because the powder and aggregates form a dense cementitious matrix, which creates difficulties for the movement of moisture after drying begins. In addition, special atmospheric conditions are required for drying. If the external surface of the concrete dries before the internal part hardens, this can lead to a weaker structure of the product.

It is difficult to obtain the exact moisture content inside the concrete, because the powder and aggregates form a dense cementitious matrix, which creates difficulties for the movement of moisture after drying begins. In addition, special atmospheric conditions are required for drying. If the external surface of the concrete dries before the internal part hardens, this can lead to a weaker structure of the product.

Farnam’s laboratory wanted to develop an aggregate product that would have optimal mixing, strength and porosity characteristics, and find a way to make it from a large amount of waste.

Coal ash - a by-product of coal-fired power plants, which is obtained as a result of burning coal. Every year, hundreds of tons of ash are sent to a landfill. Researchers at Drexel University believe they have found the use of a powdery residue. They are confident that ash can make concrete more durable and crack free.

Company development Farnam

“The solution we came up with was the processing of coal ash waste into a porous, lightweight aggregate with superior performance that can be produced at a lower cost than existing natural and synthetic options,” said Farnam (founder of the idea).

It is scientifically proven that the presented additive will significantly increase the service life of concrete, make it much stronger. The concept of internal hardening was developed in the last decade; a porous lightweight aggregate is used to facilitate the curing process. The additive can maintain a constant level of moisture inside the concrete to help it cure evenly from the inside.

Calcium silicate in concrete

Micro spheres made of calcium silicate were developed by scientists from Rice University. It is proved that the invention will help to obtain a more durable and environmentally friendly concrete, with improved mechanical properties (strength, hardness, elasticity and durability) than Portland cement, the most common binder used in concrete. The size of the spheres is from 100 to 500 nanometers in diameter. Their use promises to reduce the energy intensity of cement production (one of the most common binders in concrete). Shahsavardi claims that the spheres are suitable for bone tissue engineering, insulation, ceramics and composite applications, as well as cement.

According to Shahsavardi, an increase in cement strength will contribute to:

- Reduce the weight of concrete.

- Less material consumption.

- Reduced energy consumption during concrete production.

- Reducing carbon emissions during the manufacturing process.

The scientist said that the size and shape of the particles as a whole have a significant impact on the mechanical properties and durability of bulk materials such as concrete.

Recycled tire concrete

UBC engineers have developed a more resilient type of concrete using recycled tires. The substance can be used for concrete structures such as buildings, roads, dams and bridges. At the same time, the volume of waste in landfills will be significantly reduced.

Researchers experimented with various proportions of recycled tire fibers and other materials used in concrete — cement, sand, and water — before they found the perfect mix. It consists of 0.35% of tire fibers. In the USA, Germany, Spain, Brazil and China there are already asphalt roads with crumb rubber from crushed tires.It is proved that the presence of these particles has contributed to improving the elasticity of concrete and extending its service life.

Tire Concrete Test Results

Laboratory tests have confirmed that fiber-reinforced concrete reduces cracking by more than 90 percent compared to the classic mix. This is due to the polymer fibers that overlap the cracks as they form, helping to protect the structure and extend its service life.

Laboratory tests have confirmed that fiber-reinforced concrete reduces cracking by more than 90 percent compared to the classic mix. This is due to the polymer fibers that overlap the cracks as they form, helping to protect the structure and extend its service life.

“Most of the worn tires are for disposal. Adding fiber to concrete can reduce the carbon footprint of the tire industry, as well as reduce emissions in the construction industry, as cement production is a significant source of greenhouse gas emissions, ”said Bantia, UBC's research director.

New concrete was used forfacing of steps in front of the Macmillan building on the UBC campus. The Banthia team monitors its condition with sensors embedded in concrete, monitoring the development of stress, cracks and other factors. At the moment, the observation results confirm the results of laboratory tests and indicate a significant reduction in cracking.

How to avoid the destruction of concrete from sulfuric acid?

The atmospheric and chemical effects on the concrete coating adversely affect its condition. The destruction of concrete from sulfuric acid can be avoided by finding ways to prevent the adsorption of its gas precursor into concrete. In the course of his research, Matthew Lasich discovered that in order to protect the concrete infrastructure from corrosive effects, preliminary treatment is needed aimed at the adsorption sites in cement hydrate, where most hydrogen sulfide molecules are attached. However, this approach may be difficult due to their widespread use.

The atmospheric and chemical effects on the concrete coating adversely affect its condition. The destruction of concrete from sulfuric acid can be avoided by finding ways to prevent the adsorption of its gas precursor into concrete. In the course of his research, Matthew Lasich discovered that in order to protect the concrete infrastructure from corrosive effects, preliminary treatment is needed aimed at the adsorption sites in cement hydrate, where most hydrogen sulfide molecules are attached. However, this approach may be difficult due to their widespread use.

The porous structure makes concrete vulnerable to adsorption of natural gas. In their study, the authors conduct nanoscale analysis based on Monte Carlo simulations to simulate the migration of gas molecules into the structure of cement hydrate. Their modeling suggests that for a good absorption of cement hydrate a certain combination of molecule size and surface area is required.