How to choose a laminate?

What is laminate flooring?

Of the many types of flooring, laminate flooring is one of the most popular decorative flooring on the market. This is due to the fact that the material has practicality in use, attractive appearance and a variety of colors and textures, attractive cost, which is several times lower than parquet floors. In addition, laminate floors can do it yourself since the simplicity of the connection design allows you to easily mount panels on the floor surface.

Of the many types of flooring, laminate flooring is one of the most popular decorative flooring on the market. This is due to the fact that the material has practicality in use, attractive appearance and a variety of colors and textures, attractive cost, which is several times lower than parquet floors. In addition, laminate floors can do it yourself since the simplicity of the connection design allows you to easily mount panels on the floor surface.

Modern laminate is sometimes superior parquet board in durability, since some of its samples with high strength are practically not inferior in properties to the more expensive parquet coating. Previously, laminate flooring was called “laminated flooring”. Of course, the floorboard has a large service life, but the high cost, the complexity of laying and the inability to do this on their own does not allow to attribute it to the budget flooring. Laminate flooring also allows you to get a quality finished floor with a minimum budget.

The pioneer in the implementation of laminated panels is the company from Sweden PERSTORF, which undertook to promote products in the construction market. The company's specialists decided to use laminated panels for kitchen sets as a floor covering and did not fail. The new material was a great success, and quite quickly the company entered the international level. This happened in 1977, and after almost thirty years, the laminate became more sophisticated and diverse. Modern production technologies and the use of the latest materials give an excellent finishing floor covering.

The name laminate comes from the English word "laminate", which means "material from the layers." This is because the panels are several layerswhich provide appropriate durability and attractiveness. This finishing material is a panel with a thickness of 7-12 mm, a width of about 20-25 cm and a length of 1 to 2.5 meters. Laminated panels are not made from a single piece of wood and consist more of artificial materials. This does not mean that the environmental safety of the laminate floor is worse than that of a natural parquet board.

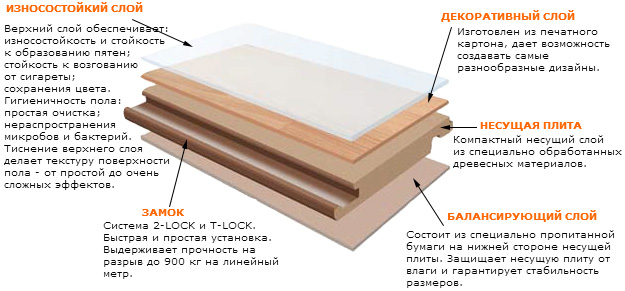

To better understand the properties and capabilities of this flooring, let's look at the design of its panels.

What is laminate flooring made of?

Layer-by-layer structure of laminate flooring

- First layer - the most important layer, which is also called an “overlay” and ensures the laminate's resistance to abrasion of the surface, exposure to chemicals, protection against moisture, resists pollution and direct sunlight. Such a barrier of protection provides a special film of acrylic or melamine resin. The protective film may have several layers, which gives greater strength and surface resistance to external influences.

- Second layer - the next layer is decorative, that is, it is a pattern or texture that imitates natural wood or other similar material. This layer is also important, since the choice of color and design of this or that depends on it. laminate flooring from various manufacturers. As a rule, this layer of special paper imitating a tree of various breeds and textures, but this is not necessary. The surface can be made under the tile or stone surface, there are also other colors, such as plain white or any other color.

- Third layer - this layer is the main, that is, the bearing, which determines the durability of the laminated panels, resistance to bending and resistance to shock. The main layer is a wood board made of fiberboard or chipboard, which have a high density in order to effectively resist not only physical influences, but also moisture penetration. In addition, this layer determines the thickness of the panel, which ranges from 7-12 mm.

- Fourth layer - and finally, the last layer of the laminate flooring is a layer of paper impregnated with a special resin. It protects the inner surface of the wood "third" layer from moisture penetration and deformation of the geometry of the entire plate, which can occur when the humidity level changes and temperature fluctuates.

Additional layers and other features

In addition to these layers, manufacturers can use additional layers for property improvements laminate flooring. To increase strength, a layer of aluminum dioxide or a corundum microparticle can be added. Antistatic is added to repel dust from the floor surface, which is very useful for people who do not particularly often wet the room. Also, the panels can be pressed in such a way as to take the appropriate structure of the decorative surface.

In addition to these layers, manufacturers can use additional layers for property improvements laminate flooring. To increase strength, a layer of aluminum dioxide or a corundum microparticle can be added. Antistatic is added to repel dust from the floor surface, which is very useful for people who do not particularly often wet the room. Also, the panels can be pressed in such a way as to take the appropriate structure of the decorative surface.

All layers are interconnected according to one of two technologies. This technology is high (HDL) and low (DLP) pressure. In the case of HDL, the first few layers of films and the decorative layer are combined under the influence of high temperature and pressure of the press, then pressing occurs with the main and reverse parts of the panel. With DLP, the first two layers and the backcoated base layer are pressed in a single step.

The most common type of joint laminate panels among themselves is castle system, which allows you to securely fasten them together. There is also an adhesive type of connection, but it is no longer used in modern locking systems. Each manufacturer tries to use its own panel connection system, but the idea of implementation is common, so the choice will fall on the manufacturer who likes it more.

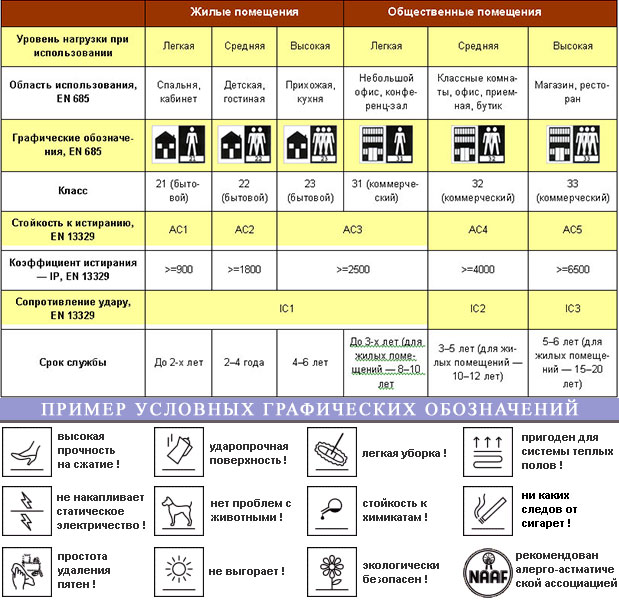

Laminate Classes

Each brand of laminate has a certain set of characteristics of resistance to external influences, in accordance with which a class of use is assigned. This class is assigned after 18 trials. The following classes of laminate flooring are found in accordance with EN13329 (EN13329 - European norm, which came into force on 1.02.1999. Previously, another norm was usedEN 438.) and they are indicated by two-digit numbers - these are: 21, 22, 23, 31, 32, 33, 34, 35, 36, 37, 41, 42, 43.

Each brand of laminate has a certain set of characteristics of resistance to external influences, in accordance with which a class of use is assigned. This class is assigned after 18 trials. The following classes of laminate flooring are found in accordance with EN13329 (EN13329 - European norm, which came into force on 1.02.1999. Previously, another norm was usedEN 438.) and they are indicated by two-digit numbers - these are: 21, 22, 23, 31, 32, 33, 34, 35, 36, 37, 41, 42, 43.

- First digit each class indicates the type of room for which the flooring is intended.

- Second digit indicates a possible level of operating intensity.

The first group with an initial number of 2 is intended for residential premiseswhere the intensity of the physical impact on the surface is not so high.

The first group with an initial number of 2 is intended for residential premiseswhere the intensity of the physical impact on the surface is not so high.- The second group with the number 3 indicates that this type of flooring is intended for office and retail premises, where the intensity of loads on the floor surface is much higher, therefore this class shows a more durable and durable floor covering.

- The third group with the number 4 indicates that this type of flooring is intended for industrial premises.

Household Laminate

Laminate classes 21, 22, 23 Designed for rooms with a low intensity of the load on the floor surface. The service life of such a coating is about 3-5 years. Elementary classes are perfect for a bedroom or basement. The cost of such a laminate ranges from 10 cu Most manufacturers have already discontinued products of this class.

Commercial Laminate

Next group of classes 31, 32, 33, 34, 35 possesses greater wear resistance and is used in rooms with intense physical impact on the floor in office and other crowded places. He also gained great popularity in the household sector, for this reason most companies stopped producing laminated panels of 21, 22 and 23 classes. Of course, the cost of such a floor will cost twice as much, about 20 cu The term of use of the latter is also twice as high.

Laminate premium for industrial premises

Laminate premium class 41, 42 and 43 is not so widespread and is available on special order. An example of its use can be seen at Sheremetyevo Airport, 42 class is laid there.

Laminate advantages

Choosing this flooring, the user is guided by its main advantages, the main of which are its practicality. You will need a minimum of effort to look after him. On a high-strength laminateno scratches or dents leftthat can form from furniture wheels, women's shoes with stilettos, or other similar means. And even if a heavy object falls to the surface, then there will be no trace.

Choosing this flooring, the user is guided by its main advantages, the main of which are its practicality. You will need a minimum of effort to look after him. On a high-strength laminateno scratches or dents leftthat can form from furniture wheels, women's shoes with stilettos, or other similar means. And even if a heavy object falls to the surface, then there will be no trace.

Another positive property that will tip the scales in favor of the laminate is its waterproof coating, which does not harm the environment environmentally. This is very important for people allergic, sensitive to natural materials. The material is perfect safe and environmentally friendly. In addition, the coating is resistant to high temperatures, so even ash from a cigarette butt or outgoing heat from a heating device falling on the laminate floor will not harm him.

Another useful property is resistance to chemicalsthat may be accidentally spilled onto the surface of the laminate floor. It can be paint or nail polish. It is enough to remove the formed dirt or stain with acetone without harming the outer and decorative layer, stains or scuffs from the caustic solvent will not remain. This coating does not require special care, as it is necessary for the operation of parquet. And probably main advantage Is the availability of the laminate in terms of cost and simplicity of layingthat can be done independently.

Laminate disadvantages

Particular attention when buying laminated panels for your floor should be given to the edges, that is, the locking systems that connect the panels to each other. Some little-known manufacturers are not responsible for this issue. As a result of violations of the production technology of laminated floor panels, elements of castle joints can be fragile, which will lead to the separation of the panels during operation. The best way to protect yourself from such moments is to acquire products of famous manufacturerswho have proven themselves in the market of building and finishing materials. For instance, Perstort Flooring (Sweden), KAINDL (Austria) or Witex (Germany) have excellent quality and will not let their users down.

Particular attention when buying laminated panels for your floor should be given to the edges, that is, the locking systems that connect the panels to each other. Some little-known manufacturers are not responsible for this issue. As a result of violations of the production technology of laminated floor panels, elements of castle joints can be fragile, which will lead to the separation of the panels during operation. The best way to protect yourself from such moments is to acquire products of famous manufacturerswho have proven themselves in the market of building and finishing materials. For instance, Perstort Flooring (Sweden), KAINDL (Austria) or Witex (Germany) have excellent quality and will not let their users down.

The next negative point is laminate durability. As you already know, the low class of panels has a service life of about 7 years, and the class above can have 20 years.This is not a long time for flooring, since high-quality parquet will last two to three times longer. It should be understood that with too much use of the floor, the durability will be significantly reduced and will be 3-10 years, depending on the class. It is impossible to cycle the laminate floor, as happens with a parquet board, so if one of the panels is damaged, it will be completely replaced. Keep this in mind and purchase flooring with a margin for such cases.

Another negative feature of the laminate is its resonating property, makes a loud sound when any object falls on it. This is due to the use of fiberboard and particleboard as the basis of the panels. They amplify the sound when falling or hitting the surface. In addition, the laminate floor consists more of artificial materials, so for connoisseurs of natural wood finishes, this option is not suitable.

Water resistance of laminated floor panels

Although, as mentioned above, the laminate has a good resistance to water, thanks to the protective first layer, nevertheless when moisture gets under the panel even the toughest laminated surface may deform. The basis of fiberboard and particleboard panels is a wood-based material that absorbs moisture well, despite the special water-repellent additives. Therefore, prolonged exposure to moisture leads to deformation of products from these materials.

The protective layer allows wet cleaning using chemical detergents. A prolonged stay of the laminate under the influence of moisture can adversely affect it. Deformation and damage to the flooring will occur. Not long panels are allowed in water - it is about 4 hours. If the floor was wet during this time or even less, then you should wipe it well, and it is better to remove and completely dry it.

What laminate flooring to buy: tips for choosing taking into account operating conditions?

At first, decide which room the cover will be used for. To do this, understand the purpose of the classes that have been described above. Consider the load, which will be attached to the flooring - it can be furniture, the intensity of walking, that is, if it is an office, then naturally it will be more resistant to abrasion from intensive walking on it with shoes. Pay attention to the thickness of the panels, the larger it is, the stronger and more stable the floor surface will be, but the cost is naturally higher.

When buying, check with the seller Taber value, which indicates the level of abrasion of the laminate. This test shows the number of revolutions when grinding its surface, which is required for the appearance of an abrasion defect.

- For class 21, 22, 23 this figure is about 11 thousand revolutions,

- and for 31, 32, 33 classes, the value reaches 20 thousand revolutions.

From this you can judge how strong and durable your floor covering will be. The type of connection of the panels is also very important, although the castle structure is present in any modern laminate, you should choose eminent manufacturers with a good reputation if you want the floor surface to last a long time.