Quality of flooring: parquet, laminate, linoleum

The flooring in the room is one of the most important elements of the interior and its selection from many types will be very important. Particular attention requires consideration of quality parameters. flooringA careful study of which will help you choose the best option. Choosing a solid floor covering you will get not only the durability of the floor, but also good heat and sound insulation characteristics of the room.

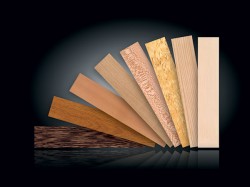

Of the many types of decorative floor coverings that the modern construction market represents, let's look at three main ones - these are parquet, laminate and linoleum. All three types have a number of operational characteristics, which can vary both between types, and between wear resistance classes, and various models. To choose the most optimal and affordable option from a variety of products from the mass of manufacturers, one should understand the basic criteria and characteristics by which the quality of the floor covering is determined. After reading the article, you will get an idea of the parameters that will help you make the right choice.

How to determine the quality of the parquet?

Parquet Features

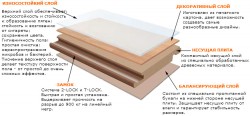

To better understand how high-quality flooring you need to first understand what it consists of. If you thought that parquet board made of solid wood, you are mistaken, it has a multilayer structure. Each layer carries a certain function, which together determine the quality of the parquet. So, let's take a closer look at each layer individually.

To better understand how high-quality flooring you need to first understand what it consists of. If you thought that parquet board made of solid wood, you are mistaken, it has a multilayer structure. Each layer carries a certain function, which together determine the quality of the parquet. So, let's take a closer look at each layer individually.

- Upper layer - This layer is primarily decorative. Its abrasion resistance is determined by the hardness of the wood, different types of wood have different strength characteristics. The top layer, as a rule, is made of valuable species of wood, such as oak, beech, aspen, maple, pine and many others. Usually this layer has a thickness of 4 millimeters, which is quite enough for the parquet to last 10 years without any complaints. The smaller the thickness of this layer, the less durable the parquet coating. The thickness of the top layer determines the number of grinding cycles.

- Middle layer - the next layer, which consists mainly of pine or other coniferous wood. Its thickness ranges from 8 to 10 millimeters. This layer is important in that it is a joint, that is, at this level there is a lock that holds parquet boards together with honey. It is important that the layer does not consist of a solid tree, but is formed of many planks located perpendicular to other layers of the parquet board. This is required for better stability of the parquet to differences in humidity, temperature and a more durable connection with other parquet boards.

- bottom layer - The last layer is fixing and secures the middle layer. This is solid plywood, which is the final link in the parquet, and has a thickness of about 2 millimeters. It has no special parameters, so it does not require close attention.

Criteria for choosing quality flooring

First of all, the choice of parquet determines it appearance and texture. If the top layer has a non-uniform color scheme and has various defects that are inherent in a tree, such as knots or uneven annual rings, then this indicates a not very high-quality wood material. This does not mean that it is less durable, but such a parquet will not cost much and will not look as impressive as a parquet board made of high-quality wood.

First of all, the choice of parquet determines it appearance and texture. If the top layer has a non-uniform color scheme and has various defects that are inherent in a tree, such as knots or uneven annual rings, then this indicates a not very high-quality wood material. This does not mean that it is less durable, but such a parquet will not cost much and will not look as impressive as a parquet board made of high-quality wood.- One of the main criteria for the quality of parquet is its hardness. This is determined by the type of wood that is used for the top decorative layer. There are five classes of hardness, which determine the quality and high cost of a parquet board.

- First grade - This is the hardest tree species, such as iron tree, boxwood, merbau.

- Second class - this is hornbeam and ash.

- Third class - this is beech, oak, maple, elm. The fourth class is aspen and soft birch. The fifth class is the softest species, which include cedar, pine or linden.

- To make the right choice, you need to pay attention to marking on the floor. Look carefully at certificate of conformity with GOST, and quality certificate from the manufacturer and the same for hygiene safety. If you meet too much praised goods, this is a sign that the products are not of the highest quality. A self-respecting manufacturer clearly knows the price of its product, and will not deceive the buyer.

How to determine the quality of the laminate?

Laminate Features

Like parquet, the laminate has a multilayer structure. It is not made from natural wood materials, which are modern analogues of pressed wood with the addition of binders. These are fiberboard, MDF, chipboard or HDF, which are most often used in the manufacture of laminated coatings. Laminate is a more practical floor covering due to its low cost and excellent parameters of durability and strength. But this material has a number of characteristics that indicate the quality of the coating. Let's look at the layers that make up a laminate.

Like parquet, the laminate has a multilayer structure. It is not made from natural wood materials, which are modern analogues of pressed wood with the addition of binders. These are fiberboard, MDF, chipboard or HDF, which are most often used in the manufacture of laminated coatings. Laminate is a more practical floor covering due to its low cost and excellent parameters of durability and strength. But this material has a number of characteristics that indicate the quality of the coating. Let's look at the layers that make up a laminate.

First layer - This is the top protective layer that protects the panel from external influences. This layer gives abrasion resistance and is one of the most important. A layer is a protective film, also called an overlay. It can be implemented in several layers, which gives greater stability.

First layer - This is the top protective layer that protects the panel from external influences. This layer gives abrasion resistance and is one of the most important. A layer is a protective film, also called an overlay. It can be implemented in several layers, which gives greater stability.- Second layer - This is a decorative layer that mimics the surface of natural materials. The most common, probably the only one, is wood stylization, but there are other imitations, such as natural stone or other material and color. This layer is a special paper that has a large number of textures and colors.

- Third layer - is the basis for other layers and is made of fiberboard, MDF, particleboard or HDF. Depending on the use of one or another basic material, the strength of the laminate is determined. For example, HDF is a high-density wooden base, which gives the laminate floor even greater strength and durability.

- Fourth layer - a special coating of paper, impregnated with a resin composition, which prevents the penetration of moisture into the main layer. It also protects the wood board from deformation due to changes in temperature and humidity.

Criteria for choosing a quality laminate

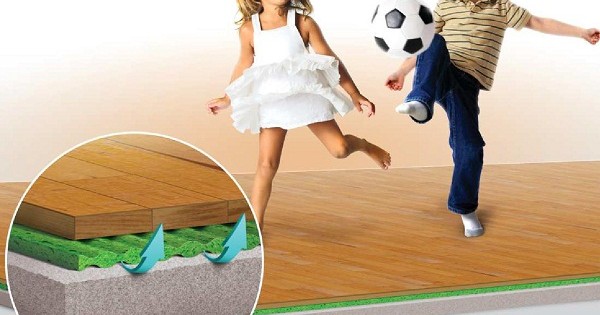

Laminate flooring divided into classeswhich indicate the degree of strength of the floor covering. Higher grade, the more stable and stronger such a floor. The most popular are 21, 22, 23, 31, 32, 33 classes of laminated panels. The first three with the first number 2 indicate a low degree of strength and abrasion resistance. This means that for places where there is an intense flow of people, that is, in an office, store or other similar place, it is better not to use such a laminate.The last three with the first number 3, on the contrary, have good strength indicators and can be used in crowded places.

Laminate flooring divided into classeswhich indicate the degree of strength of the floor covering. Higher grade, the more stable and stronger such a floor. The most popular are 21, 22, 23, 31, 32, 33 classes of laminated panels. The first three with the first number 2 indicate a low degree of strength and abrasion resistance. This means that for places where there is an intense flow of people, that is, in an office, store or other similar place, it is better not to use such a laminate.The last three with the first number 3, on the contrary, have good strength indicators and can be used in crowded places.- Also worth pay attention to the third main layer of the board itself. As mentioned above, it can be fiberboard, MDF, particleboard or HDF. The latter material has the highest strength and can withstand high bending and deformation loads. Other types are less durable, so it is chosen based on the needs of the user who decides to buy a laminate.

- The next point is Castlewhich connects the laminated panels to each other. Famous manufacturers use their own developed designs of such locks that can withstand stretching and can not be deformed. There are two types of locks - these are Click and Lock. In simple terms, the first option is a snap-on design, and the second is a pad design. Both options are very reliable and you should choose based on your own convenience.

- When choosing a laminate, first of all, you should pay attention to products from well-known and well-established manufacturers.

How to determine the quality of linoleum?

Characteristics of linoleum

Linoleum is the most affordable and simple flooring, so it is in great demand. It is most often used at home and in the office for its practicality and rather good physical properties of strength and resistance to abrasion. Linoleum has a different configuration and also has characteristics that determine its quality. Basically, linoleum consists of two parts, which we will consider in more detail below.

Linoleum is the most affordable and simple flooring, so it is in great demand. It is most often used at home and in the office for its practicality and rather good physical properties of strength and resistance to abrasion. Linoleum has a different configuration and also has characteristics that determine its quality. Basically, linoleum consists of two parts, which we will consider in more detail below.

- Front side - the decorative side of linoleum, which is made of a polyurethane base. The better this layer, the more stable the overall flooring of linoleum. Linoleum can be divided into commercial and household, in the first case, the drawing passes through the entire thickness of the layer, in the second only from the top. Therefore, commercial linoleum is the strongest and can withstand significant daily loads of 5 tons per square meter and will last quite a while without losing the pattern of the upper face layer.

- Substrate - This is the lowest layer, which is the base and has the property of insulation. But it can be just a polyurethane durable coating without insulation. The thickness of the lower layer of linoleum does not indicate its strength. If the substrate is soft, as a rule, such linoleum is well soundproofed and retains heat. It is well suited for home, but also for the office will be very useful.

Criteria for choosing quality linoleum

Determine the quality of linoleum possible on such grounds - this embossed texture, which has a good thickness, as a rule, a very high-quality, bright design solution, that is, a high-quality drawing, also speaks of the good quality of linoleum.

Determine the quality of linoleum possible on such grounds - this embossed texture, which has a good thickness, as a rule, a very high-quality, bright design solution, that is, a high-quality drawing, also speaks of the good quality of linoleum.- Linoleum stability is better in commercial type, since it is designed for intense loads of human legs and other factors. The PVC coating of the first layer should have a pattern that runs across the entire thickness of the layer. This is the main indicator of high-quality and durable linoleum flooring.

- Another important factor is the manufacturer, which produces linoleum. Well-known brands care about their reputation and keep the brand, producing a high-quality and durable product.